“It is a fantastic opportunity and a dream come thru- to start a new car design from scratch with the goal of creating the ultimate driving experience” Dr. Thomas Johansson

After more than a decade of designing Hypercars it is time to use that knowledge and experience to create a new Supercar- a driver focused car without any compromises.

With a holistic design view and use of the latest computer software’s- the Atora design was created. Every part and every design were carefully chosen to fulfill function, form, manufacturing, assembly, cost and safety.

Chassis

The foundation of the Atora Supercar is the class leading chassis strength. With a wheel to wheel torsional rigidity of 40,000 Nm/°, the foundation is set for exceptional handling and an extremely safe structure.

The monocoque chassis takes inspiration from motorcycle design with two super strong aluminium beams on the sides that is joined at strategic places. The optimized chassis consist mainly of laser cut sheets of varied thickness and CNC´d plates at high stress locations. One unique feature is the almost bracket free design where components mounts are done directly into the chassis. This could only be done by finalizing the designing of the chassis as one of the last pieces- a feature most of the manufacturers can only dream on!

The chassis is made like a gigantic 3D puzzle that can only be put together in one order and even becomes its own jig before the laser welding. To further increase stiffness and safety the internal volume of the monocoque is filled with a specially formulated sandwich core material.

These features make for remarkably rapid and easy way to manufacture and update the chassis for any changes without any real tooling modifications- therefore the trademarked name: Rapid Production ChassisTM or RPC

The upper cockpit structure serves as an integrated roll cage made by tubular high-strength steel. Together with the large deformation zones in the monocoque it forms a highly safe structure.

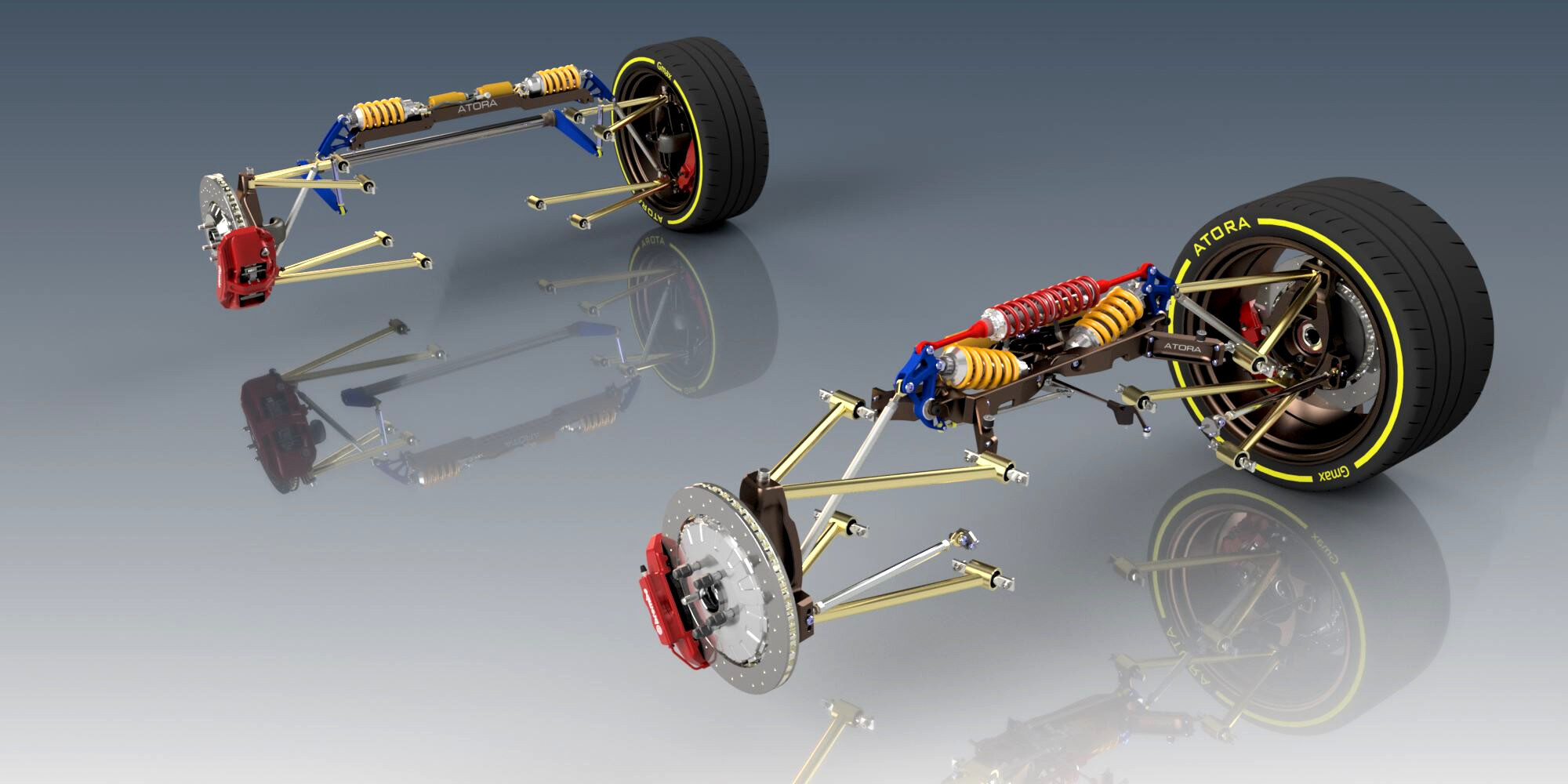

Suspension

Extra long A-arms, pushrod operated rising rate suspension, triple spring, advanced anti-roll bars, minimized feed of suspension forces into the chassis. These are the ingredients for optimum vehicle dynamics that Atora aim for and can normally only be found in pure racing cars.

The suspension geometry has to balance likely driving conditions and Atora has found the perfect combination to get superb camber control in roll, bump, and normal track speed steering angels. At the same time the track width variation is kept as small as possible, which all is helped by the the extra long A-arms in the Atora.

Brakes

The Atora brakes are precisely adapted to the engine power and the suspension design. The internally vented and cross drilled steel brake discs achieve constant braking effect in all conditions. The monobloc brake calipers provides high rigidity for maximum feeling and also forms an integral part to the upright to handle huge braking and driving loads. To lower the CoG, they are mounted in a extremely low position for a road going car. The 20″ tires makes room for the large brake system.

The ABS control algorithm ensures improved wheel slip control and enhance brake performance with respect to actual downforce. It offers adjustable sensitivity and control characteristics for operating as close to your vehicle’s limits as possible.

Steering

One of the most important feature for any sport car is the steering feeling, getting the driver to sense the driving conditions is extremely rewarding. Atora choose to have hydraulically assisted steering with proven power assist ratio, scrub radius and Ackerman settings. The bump steer is eliminated by careful steering and suspension geometries for a wide range of camber settings.

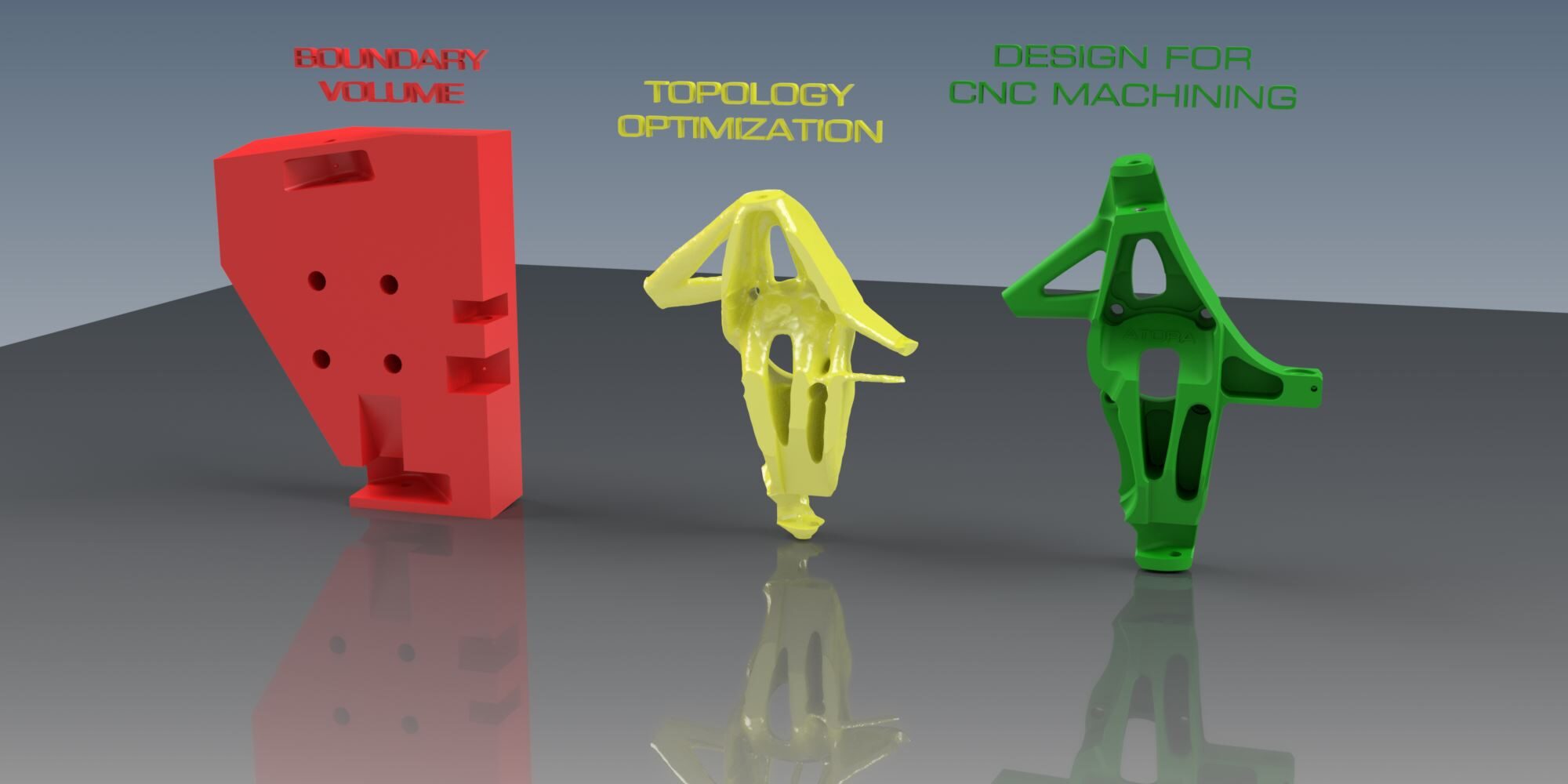

Simulation

Atora uses the latest in Computer Aided Engineering or CAE tools to bring designs to life. The first step is to simplify and looking for combined functions. All stressed parts are then analyzed with topology optimization that find the best design for a multiple of boundary conditions. The design is then verified with extensive stress or eigenfrequency analysis in different FEA programs depending on complexity. The Atora design is heavily aero influenced and CFD analysis is the main tool there.

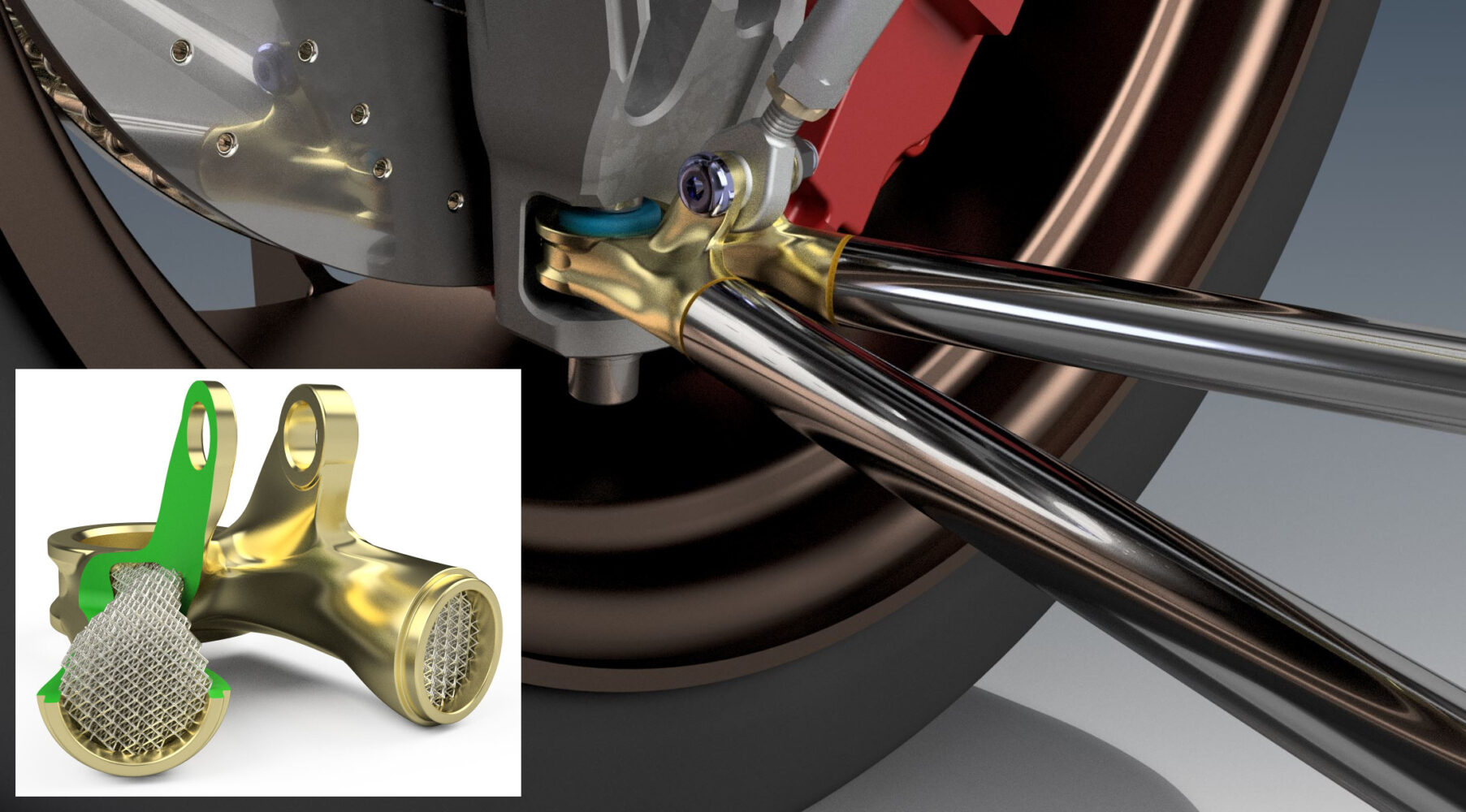

3D printing

To take full advantage of the result from the topology optimization some parts are manufactured with metal 3D printing. One good example is the A-arm end that normally is made with many parts- that needs to be welded together. A 3D printed part combines these to a single unit and in the end gets stronger, lighter and more cost effective with much better tolerances.

Weight

The end result is a car that weights below 1350 kg, complete with all the liquids.